Globalisation and Diversified International Patterns of Consumption

Title: With the evolution of human communication and transportation modes over decades and centuries, this world is squeezing smaller and smaller day by day in terms of interaction among people of different regions, ethnicity, races, and obviously different mind-sets. This changing characteristic of the world is perceived as the globalisation and the world is seemed to be a global village. The globalisation of this world has changed certain patterns of its villagers in terms of their thoughts, lifestyle, communication, buying and selling trends, and also their patterns of consuming the goods and commodities. The contemporary and recent researches on the cultural issues targeted the process of cultural change among migrants and minority people within the mainstream strata of a given culture; however, limited research is conducted on the behavioural transformation as a product of globalisation (Sobol, Cleveland, and Laroche, 2014).

This research essay is purposefully written to explore the underlying scenario related to this topic by including and referring to different literature and viewpoints of the scholars and experts. The theme of this essay will be to discuss and assess the aftermaths of globalisation on transforming the behavioural patterns of the people towards consumption of goods.

Globalisation Definition

The term ‘globalisation’ not only encompasses the economic and trading practices, but also the human agents or the practitioners whose behavioural attributes can impact the globalisation phenomenon itself. In this way, the globalisation curtails the influence of cultural or societal differences related to paradigm development and also widens its scope while including the economic and financial activities regarding consumption of services and products. Another understanding of the world globalisation can be established by considering it as the international transfer or exchange of public, money, commodities, knowledge and the cultural norms, which resulted in the boosting the awareness level of people in the two last decades of the last century (Jadoon, Butt, and Hayat, 2016).

In the context of social sciences including culture, sociology, political science, and also economics, the term globalisation is treated as comprising the international classification, electronic media, and the international treaty World Trade Organisation (Cornwell and Drennan, 2004).

It is explored through researches that the globalisation directly influences the patterns of consumptions and the society. The consuming trend and style a society adapts mostly rely on the development of thoughts and their needs. The significance of technological revolution in guiding the consuming patterns is pertinent for consideration. Moreover, the online shopping system has impacted the traditional trends and patterns enormously (Jadoon, Butt, and Hayat, 2016).

As per Ruediger John (2005), globalization process does not ensure the one’s freedom and security. It also lacks the definition of nations-wise social values along with the enforcement of global law pertaining to address human psychology and behaviours. Moreover, instead of politically addressing the cultural developments, the emphasis of globalisation is more on the spread and sharing of technology and economical boom (John, 2005).

Divid Howes (1996) in his book used the term homogenization which refers to the unity in the global village. The terminology depicts the paradigm of cultural and social influences in the international markets are due to the intrusion of commodities and products in the form of imports based on the knowledge gained through globalisation. This paradigm also emphasises the need to understand and accept the rise in the cultural and social differences occurred due to the export of domestic goods and the import of goods mostly produced in the western world. One contemporary contextualisation of the consumption patterns of people in the global village is the motivation of consumers or the people to choose the goods as per their own liking and disliking instead of being a blind victim of globalisation. This is because the people of the underdeveloped countries are often influenced to purchase those products which are not only new and alienated but most of the time also serves as damaging the local culture rather replacing it with the imported culture (Howes, 1996).

There is a need to go deeply to understand that the consumers’ attitude is influenced by both internal and external factors in the form of domestic culture and the consequences of globalisation respectively. Several types of research have been continuously conducted to examine the consumers with the help of examining their lifestyle. A consumer’s lifestyle is the agent of the tendency of adapting the change in behaviour for consuming items and products of a single or multiple manufacturers. It is again the globalisation which enforced manufacturers all around the world to be indulged in an extensive competition in order to win the consumer’s satisfaction. This ultimately helped the consumers in terms of having competitive quality in products (Dunn, 2015).

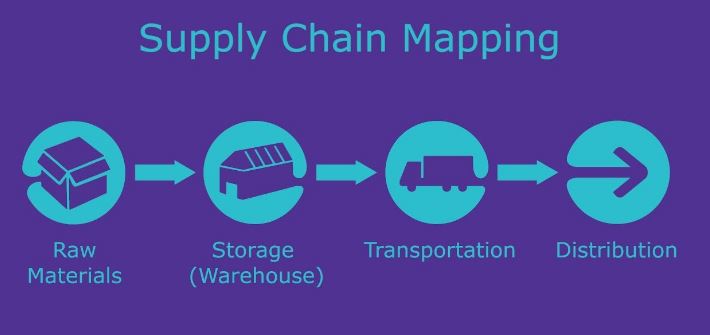

An argument in the work of Elena Kell (2012) supports that the globalisation forms and leads to a consumption based society in which consumption has become indispensible and along with its ethical practices. Consumers are generally unaware of the supply chain and operations management involved in the availability of products imported from foreign countries. Hence the ethical aspect of consumption addresses the consumer’s responsibility to be updated of the steps involved in the processes (Kell, 2012).

McCoid (2010) differentiate the consumption in its three shapes. According to that categorisation, the consumption of goods will not remain sustainable if the resources are used more than what exactly required, and this is called overconsumption. This mechanism often leads to the lower quality of life and damages the environment. On the contrary, the under-consumption is the utilisation of resources much less than the required, hence causing poor quality to health the lifestyle. It is observed that the main cause of under-consumption in the age of globalisation is the inequality in the social distribution of resources. Both forms of consumption do not contribute to sustainability. The sustainable consuming patterns, however, do not cause the environmental damage and the human health. In order to develop the consumption pattern in a sustainable way, there is a need to accept the relationship of over and under consumption with the globalisation, because in a global village, the under-consumption of most groups causes the over consumption of few groups (McCoid, 2010).

On a critical side, the contemporary consumption patterns have negatively impacted the development of human wellbeing on the individual as well as on societal levels. This change happens in a way that it spread the social inequalities among groups and even countries through globalisation. The inequalities are spread due to the differences in the quality of products and services for all different social classes within a certain society or the region. The global consumption pattern is also promoting and supporting the flow of resources to a limited class of people and groups who have much more wealth to spend on even luxurious items instead of just the basic needs, hence the poor class of people in the world continues to suffer the lacking of even basic needs due to the lack of resources. Similarly, the globalisation has intruded the consumption of food based items which are most of the times either not synchronised with the eating habits of the people of a particular country or are much expensive than their local alternatives. The adaption of foreign goods and items also often creates environmental problems in the form of waste disposal and discharge (Khor, 1998).

The increase in the free trade between countries has also enhanced the availability and quantity of goods and services for the end users. This scenario was for sure cannot be imagined the effectiveness of various global trade pacts, agreements, and the role of unions worldwide. With the increase in the quality as well as a variety of products through globalisation, the consumption pattern among people has drastically changed. People pay due importance in conducting a preliminary survey, physical or online, regarding the particular product they are going to buy. Moreover, unlike before, the brand has been given comparatively less importance by the consumers (Scriven, 2014).

The technological advancement, globalisation and the integration of countries around the world have significantly changed the consumption pattern of people all over. The internet facility got the users of around fifty million in only five years; hence it is pertinent to accept that through internet lives of thousands and millions of people in all countries evolved positively. The comparative survey has become much easier through the internet for everyone regarding any product before its purchase. Everyone in the global village can be informed of the patterns of the lifestyle of any other person or group in other parts of the world (Kónya and Ohashi, 2004).

Globalisation Conclusion

This research essay has explored different theoretical perspectives of various authors to explore the aftermaths of globalisation on transforming the behavioural patterns of the people towards consumption of goods. It can now be concluded after a comparative analysis of various viewpoints on the topic, that the globalisation has certainly opened the door of opportunities for not only sharing of knowledge, technology, and goods, but also played and has been playing a significant role in designing and changing the behavioural patterns of consumption among consumers and end users all around the world in this global village. Some paradigms consider it as positive while the other as the negative role of globalisation because, in some perspectives, it has also led towards social and financial inequalities among societies and classes of people.

References

Cornwell, T.B. and Drennan, J., 2004. Cross-cultural consumer/consumption research: dealing with issues emerging from globalization and fragmentation. Journal of Macro marketing, 24(2), pp.108-121.

Dunn, K., 2015. Globalization and consumer: What marketer needs to know. The Neumann Business Review, pp.16-30.

Howes, D., 1996. Cross-cultural consumption: global markets, local realities. Taylor & Francis US.

Jadoon, A.K., Butt, A.R. and Hayat, M.A., 2016. Development of Measurement Models for Globalization, Consumption Patterns and Culture: A Case Study of Three Big Cities of Punjab, Pakistan. Pakistan Economic and Social Review, 54(2), p.327.

John, R., 2005. Globalized Culture, Consumption and Identity. Translated by Gunilla Zedigh. Baden,

Kell, E., 2012. Ethical consumer in a globalized world: challenges for the individual’s identity. A study on ethical consumers in Lund and Malmö.

Khor, M., 1998. Globalisation, Income Distribution, Consumption Patterns and Effects on Human and Sustainable Development (no. Hdocpa-1998-06). Human Development Report Office (HDRO), United Nations Development Programme (UNDP).

Kónya, I. and Ohashi, H., 2004. Globalization and consumption patterns among the OECD countries.

McCoid, C.H., 2010. Globalization and the Consumer Society. Global Security and International Political Economy–Volume II, p.49.

Scriven, J., 2014. The Impact of Globalization on the Consumer. The Nouman Business Review, pp.13-23.

Sobol, K., Cleveland, M. and Laroche, M., 2014. Globalization, Culture and Consumption Behavior: An Empirical Study of Dutch Consumers.

Relevant Blog Posts

Globalisation Business Dissertations

MBA Project Globalization

Did you find any useful knowledge relating to globalisation and diversified international patterns of consumption in this post? What are the key facts that grabbed your attention? Let us know in the comments. Thank you.